20 1월 2020

Babcock LGE wins first cargo handling system contract for new Ethane ships at Jiangnan shipyard

Babcock’s LGE business, the global leader in liquid gas solutions, has won a cargo handling system design and supply contract for two Very Large Ethane Carriers (VLEC) at China’s Jiangnan shipyard.

Building on 2019’s strong orders in Liquefied Petroleum Gas (LPG) and ecoSMRT® Liquefied Natural Gas (LNG) cargo handling and reliquefaction solutions, these new awards mark an important milestone for Babcock LGE and a successful start to 2020 in a new market.

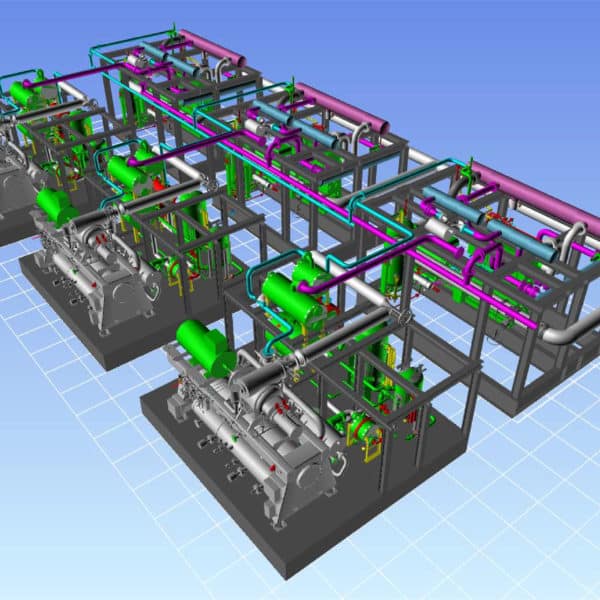

The VLEC cargo handling systems will include SuperCooler™ and ecoETHN™ technologies, both part of Babcock LGE’s Intellectual Property (IP) portfolio.

SuperCooler™ improves plant efficiency by increasing reliquefaction capacity whilst reducing energy consumption while ecoETHN™ integrates the reliquefaction plant with the fuel gas supply system by removing methane-rich Boil Off Gas, utilising it as fuel for main engine and auxiliary power generators to increase plant capacity.

Neale Campbell, Babcock LGE Managing Director, said: “Our SuperCooler™ and ecoETHN™ technologies combine to promote safe and efficient vessel operations, while delivering significant commercial advantage to the shipowner.

“We offer a portfolio of customer focused solutions and delivery of over 300 projects working with the world’s largest shipyards, such as Jiangnan.

He added: “We are delighted to have been awarded the contract and look forward to working with our customers to further the global reach of our technology.”

With more than 50 years’ experience in the liquid gas industry, Babcock LGE has a well-earned reputation for technical excellence and on-time project delivery. Several more VLECs are expected to be ordered in the coming years as the export of ethane from USA develops.